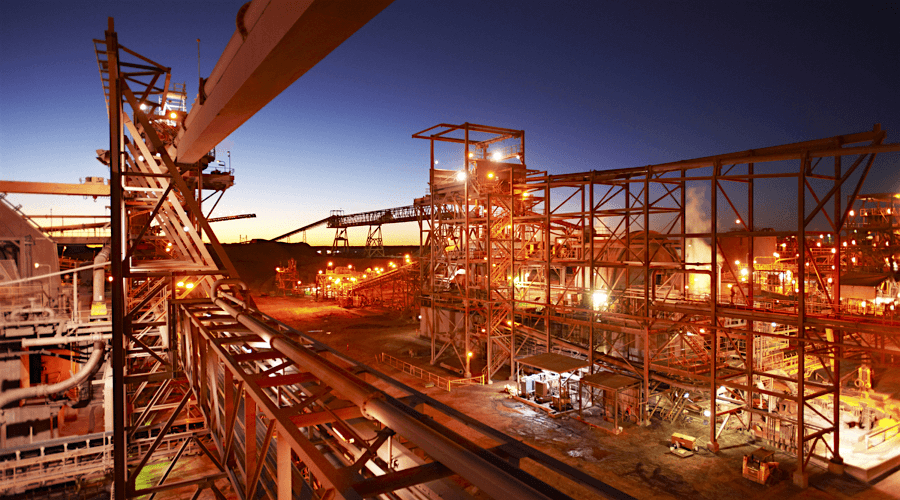

Our extensive experience has been derived from working with some of Australia’s largest companies, where we have gained leadership skills and industry knowledge through hands-on experience across all phases of project delivery. This includes project inception, concept and feasibility, detailed modelling and design, procurement, civil, SMP (Structural, Mechanical, Piping), electrical construction execution, and commissioning.

This wealth of experience has translated into our ability to oversee and manage various challenging, multi-disciplined projects involving structural, mechanical, electrical, and civil works. Our approach centres on delivering innovative and effective project execution solutions to our clients, ensuring successful project outcomes with a keen eye on quality, safety, and timeliness.